L-Shaped Staircase Calculator

Staircases are more than just a means of moving between floors—they are architectural elements that enhance both aesthetics and functionality. Among various staircase designs, L-shaped staircases strike a perfect balance between style and practicality. They save space, provide visual separation between floors, and serve as a focal architectural feature.

In this guide, we will explore everything about L-shaped staircases, from calculations and design considerations to material estimation and cost analysis. Whether you are a homeowner planning a renovation or a civil engineering enthusiast, this guide will walk you through each step.

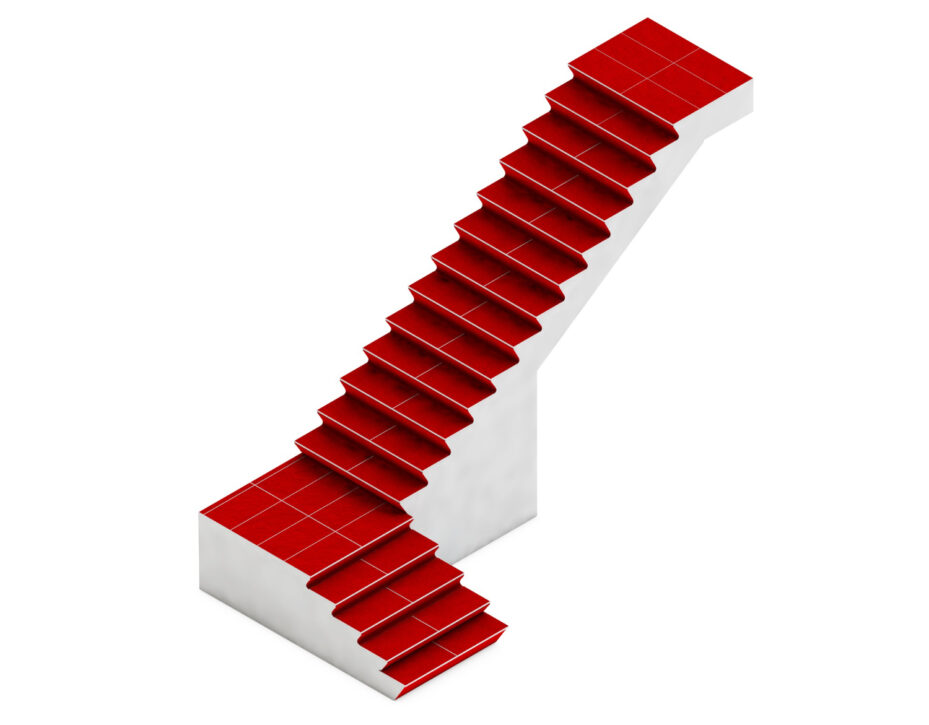

What is an L-Shaped Staircase?

An L-shaped staircase, also known as a quarter-turn staircase, consists of two straight flights connected by a landing at a 90-degree turn. This design is both visually appealing and space-efficient, making it a popular choice for modern homes.

Advantages of L-Shaped Staircases

✔ Space Efficiency: Fits well in corners, occupying less space than straight staircases.

✔ Aesthetic Appeal: Serves as an elegant design feature in homes.

✔ Enhanced Safety: The landing provides a resting point, reducing the impact of falls.

✔ Privacy: Offers a visual separation between floors compared to straight staircases.

Key Components of an L-Shaped Staircase

Understanding the main components of an L-shaped staircase helps in planning and construction:

- Treads – The horizontal steps where you place your feet.

- Risers – The vertical section between two treads.

- Stringers – The structural supports on both sides of the staircase.

- Landing – The intermediate platform where the staircase changes direction.

- Newel Posts – Large supporting posts at the start, end, and any turns.

- Handrails – Safety rails for grip and support.

- Balusters – Vertical posts supporting the handrail.

Building Code Considerations

Ensuring your staircase meets local building codes is crucial for safety and legality. Common building code requirements include:

- Riser Height: Between 150 mm (6 inches) and 200 mm (8 inches).

- Tread Depth: Minimum 250 mm (10 inches).

- Stair Width: At least 860 mm (34 inches).

- Headroom Clearance: Minimum 2 meters (6 feet 8 inches).

- Maximum Staircase Height Without Landing: 3.7 meters (12 feet).

Always check local building authority regulations before construction.

Calculating Dimensions for an L-Shaped Staircase

Accurate calculations ensure your staircase is comfortable, safe, and compliant with regulations.

Measuring Total Rise

Total Rise is the vertical distance from the finished floor of the lower level to the finished floor of the upper level.

Example:

If the total rise is 2800 mm, we proceed to the next step.

Determining Riser Height and Number of Risers

Choose a comfortable riser height that falls within code limits. A common value is 175 mm.

Calculating Number of Risers:

\text{Number of Risers} = \frac{\text{Total Rise}}{\text{Preferred Riser Height}} \text{Number of Risers} = \frac{2800 \text{ mm}}{175 \text{ mm}} = 16 \text{ risers}Actual Riser Height:

\text{Actual Riser Height} = \frac{\text{Total Rise}}{\text{Number of Risers}} \text{Actual Riser Height} = \frac{2800 \text{ mm}}{16} = 175 \text{ mm}Dividing Risers Between Flights

Since an L-shaped staircase has two flights, we evenly split the risers:

\text{Risers per Flight} = \frac{\text{Total Risers}}{2} = \frac{16}{2} = 8 \text{ risers per flight}Determining Tread Depth and Number of Treads

Each flight has one less tread than the number of risers:

\text{Treads per Flight} = \text{Risers per Flight} - 1 8 - 1 = 7 \text{ treads per flight}Using the Stride Length Formula:

2 \times \text{Riser Height} + \text{Tread Depth} = 600 \text{ mm to } 650 \text{ mm}For 630 mm:

2 \times 175 + \text{Tread Depth} = 630 \text{Tread Depth} = 630 - 350 = 280 \text{ mm}Calculating Total Run

Each flight’s run is:

\text{Total Run per Flight} = \text{Treads per Flight} \times \text{Tread Depth} 7 \times 280 = 1960 \text{ mm}Designing the Landing

The landing serves as a transition and should be appropriately sized.

- Width: Matches the stair width (minimum 860 mm, commonly 900 mm).

- Length: At least the same as stair width for comfort.

For this example, we use a 900 mm x 900 mm landing.

Material Estimation

Treads

- Quantity: 14 treads (7 per flight)

- Dimensions: 900 mm × 280 mm × 38 mm

- Total Volume:

14 \times (0.9 \times 0.28 \times 0.038) = 0.134064 \text{ m}^3

Risers

- Quantity: 16 risers (8 per flight)

- Total Volume:

16 \times (0.9 \times 0.175 \times 0.019) = 0.04788 \text{ m}^3

Stringers

Each flight requires 2 stringers.

Stringer Length (Pythagorean Theorem):

\text{Stringer Length} = \sqrt{(1400 \text{ mm})^2 + (1960 \text{ mm})^2} = \sqrt{1,960,000 + 3,841,600} \approx 2408 \text{ mm}Total volume for 4 stringers:

4 \times (2.408 \times 0.3 \times 0.038) = 0.1097376 \text{ m}^3Total Wood Volume:

0.134064 + 0.04788 + 0.1097376 + 0.03078 = 0.3224616 \text{ m}^3Estimating Costs

- Pine Wood ($500/m³):

0.3224616 \times 500 = 161.23 - Additional Materials: $60 (fasteners), $250 (handrails), $85 (finishing)

- Total Material Cost: $556.23

- Labor (50 hours × $40): $2,000

- Grand Total:

556.23 + 2000 + 255.62 = 2811.85